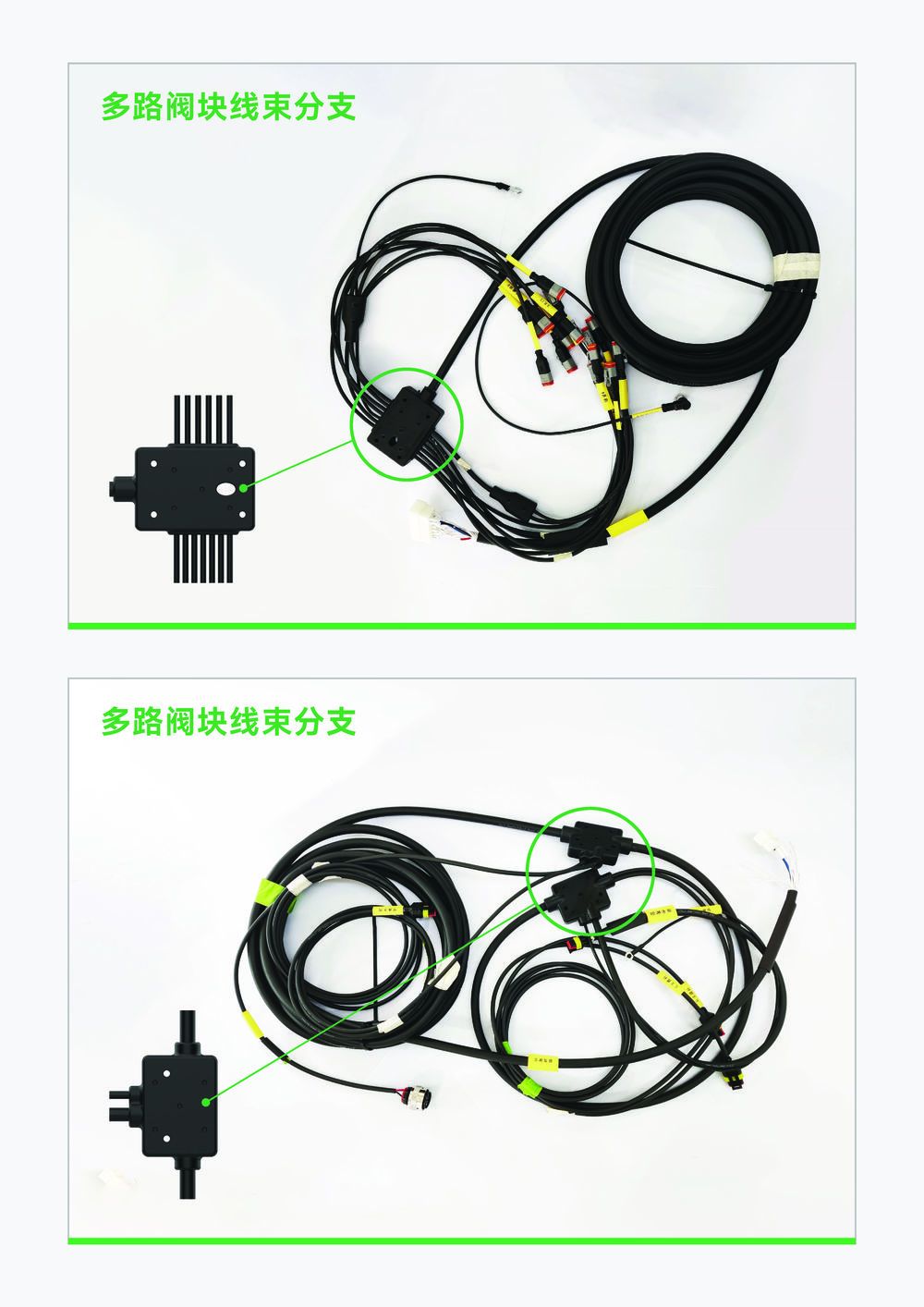

Injection Molding Harness System

The injection-molded wiring harness system has become an indispensable component in modern automobiles, electronic devices, and other industrial sectors, with its importance steadily growing. Compared to traditional wiring harnesses, injection-molded harnesses offer a superior solution. The external curing process after injection molding significantly enhances the harness's resistance to vibration and prevents loosening, ensuring reliable connections. Additionally, the sealed injection layer provides exceptional protective performance, enabling the harness to withstand harsh conditions such as oil exposure, high-pressure water, and dust ingress—achieving or even surpassing the IP67 protection rating. Furthermore, the integrated injection-molded wiring harness features a highly compact and optimized design, delivering enhanced waterproof and dustproof capabilities, as well as improved resistance to aging, impact, and vibration. This design minimizes the influence of environmental factors on connection quality. By leveraging the injection molding process, the system seamlessly integrates wires, cables, and associated components into a cohesive, orderly, and fully functional unit. As a result, not only are the electrical performance and reliability of the equipment significantly improved, but the overall spatial layout is also optimized for both functionality and aesthetic appeal.

1. Protection rating reaches IP67

It can operate reliably even in extremely harsh environments. The cable jackets in the system are made from PUR material, which not only boasts exceptional corrosion resistance, enabling long-term stable performance in a wide range of corrosive environments, but also exhibits outstanding UV resistance—so even under intense sunlight, the cables retain their original functionality and appearance.

II. Operating Temperature: -40 to 105°C

This injection-molded harness system operates across a wide temperature range—from -40°C to 105°C—ensuring reliable performance under various extreme temperature conditions, whether it's a freezing winter or a scorching summer.

III. Possess injection molding techniques and corresponding molds for mainstream connector products such as TE, ITT, Amphenol, and others.

In addition, we also possess the injection molding techniques and supporting molds for mainstream connector products such as TE, ITT, and Amphenol. This enables us to provide customers with comprehensive services—from harness drawing analysis and cable selection to connector injection molding, T-connector development, and Y-connector mold design—along with expert technical support and customized solutions.

Over the years, our injection-molded wire harness systems have been successfully deployed in mobile machinery operating in harsh environments, equipping nearly 3,000 sets of equipment. These real-world applications fully demonstrate the exceptional performance and reliability of our products—whether in challenging outdoor conditions or in complex industrial settings. Our injection-molded wire harness systems consistently deliver outstanding results, ensuring stable and dependable power and data transmission for our customers' critical equipment.

Classification:

Harness system

Key words:

Previous Page

Next Page

Previous Page

Next Page

Related Products

Immediate Consultation

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!